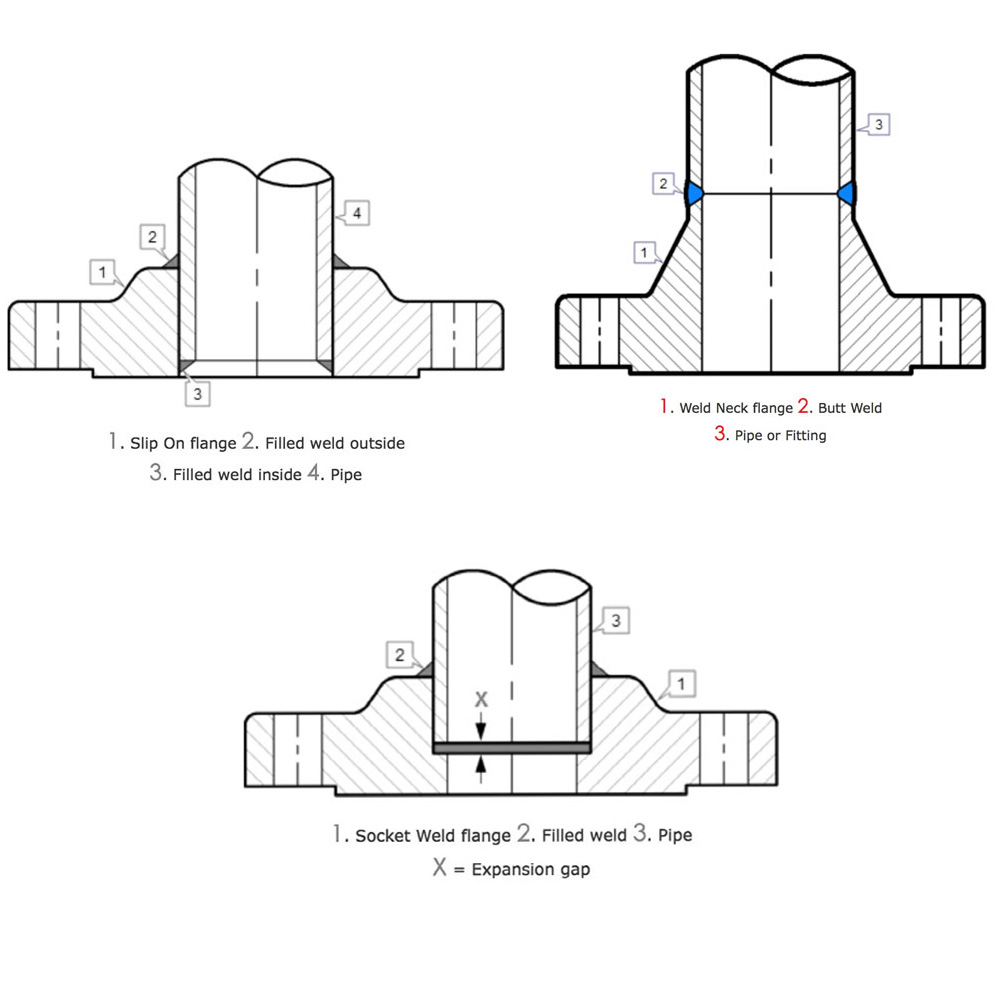

1.I-Flat welding, i-butt welding kunye ne-socket welding flange

Umbhobho welding flange unendlela yokuwelda tyaba, i-butt welding kunye ne-socket welding flange

I-Socket welding ngokubanzi ifaka umbhobho kwiiflangeyewelding.Ukuwelda kwempundu kukuweldla umbhobho kunye nempundu ngomphezulubutt welding flange,Ukufunyanwa kweRay akunakwenziwa kwi-socket weld, kodwa i-welding ye-butt ingenziwa.Ngoko ke, kuyacetyiswa ukuba kusetyenziswe i-butt welding flange kwiimfuno zokubona i-welding ephezulu.

2. Iiyantlukwano ezininzi kunye nezicelo

Ngokuqhelekileyo, iimfuno ze-welding ye-butt ziphezulu kunezo ze-welding ze-socket, kwaye umgangatho emva kwe-welding ulungile, kodwa iindlela zokufumanisa zingqongqo.I-Welding ukwenza ukubonwa kwe-ray isiphene, i-socket welding yenza umgubo wemagnethi okanye uvavanyo lokungena lunokuba (njengentsimbi yekhabhoni yenza umgubo wemagnethi, intsimbi engenasici yenza ukungena).Ukuba ulwelo olukumbhobho alufuni i-welding ephezulu, kuyacetyiswa ukuba usebenzise i-socket welding ukuze ubonwe lula.

Uninzi lweendlela zokudityaniswa kwe-socket welding zisetyenziswa kwiivalvu ezincinci kunye nemibhobho, ukufakwa kombhobho kunye ne-pipeline welding.Imibhobho yobubanzi obuncinci incinci kububanzi bodonga, kulula ukuchaneka kwaye ikhutshwe, kwaye kunzima ukuyidibanisa, ngoko ke ifaneleke ngakumbi kwi-socket welding.Ukongezelela, i-socket welding ye-socket inefuthe lokuqinisa, ngoko ke isetyenziswe phantsi koxinzelelo oluphezulu.Nangona kunjalo, i-socket welding nayo inento engalunganga.Enye kukuba imeko yoxinzelelo emva kwe-welding ayilungile, kwaye kulula ukubangela ukungena okungaphelelanga kwe-welding.Kukho izithuba kwinkqubo yombhobho.Ngoko ke, i-socket welding ayifanelekanga inkqubo yombhobho esetyenziselwa i-crevice corrosion medium kunye nenkqubo yombhobho eneemfuno eziphezulu zococeko.Ngaphaya koko, imibhobho yoxinzelelo oluphezulu kakhulu, nokuba ubungqingqwa bodonga lwemibhobho yobubanzi obuncinci nayo inkulu, inonxibelelwano oludityanisiweyo lwe-butt kangangoko ukuthintela ukuwelda kweesokethi.

Ngamafutshane, i-socket welding yenza i-fillet weld, ngelixa i-butt welding ifom ye-butt weld.Ukususela kuhlalutyo lwamandla kunye noxinzelelo lwemeko ye-weld, i-joint ye-butt ingcono kune-socket joint, ngoko i-joint joint kufuneka isetyenziswe kwimeko yoxinzelelo oluphezulu kunye nemeko yenkonzo embi.

3. Ukukhetha kweFlange

1.Ngokwemathiriyeli yombhobho ukukhetha eyona nto ifanelekileyo yeflange, efana nombhobho wensimbi engenasici ngokuqinisekileyo ayivumelekanga ukuba ikhethe.carbon steel flange ;

2.Ngokwedayamitha yesiqhelo ( DN ) yombhobho kunye noxinzelelo lwegama ( PN ) yenkqubo yonke yombhobho, ilungeloiflangeikhethiwe.Okwangoku, amazwe ngamazweumbhobho flangengokusisiseko wamkela inkqubo yomgangatho waseMelika kunye nenkqubo yomgangatho waseYurophu;

3. Ngokweemeko ezithile zokusebenza, i-flange isakhiwo kunye nefom ikhethiwe: njenge-welding flat kunye nentamo, i-loop flange, njl. .

Kwiindawo ezingekho mgangathweni, kuyimfuneko ukuyila kunye nokwenza ngokwenkqubo yoyilo lweflange.

Ixesha lokuposa: Feb-20-2023