Intsimbi yekhabhoni/intsimbi engaxutywanga ivuthele ivalve yeglowubhu

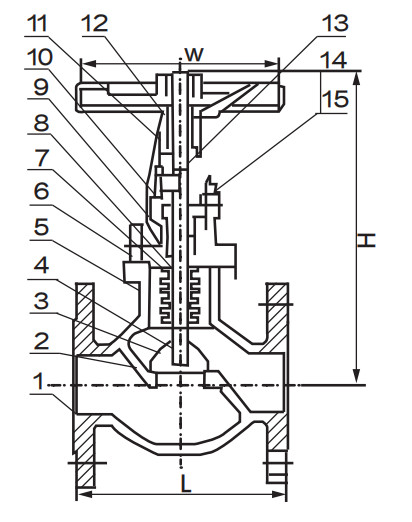

| Hayi. | Igama lenxalenye | Izinto eziphathekayo |

| 1 | Umzimba | ASTM A216-WCB, ASTM A217-WC1, WC6, WC9 C5, ASTM A351-CF8, CF8M, CF3, CF3M |

| 2 | Idiskhi | ASTM A182-Gr F6a, ASTM A182-F22, ASTM A182-F304, F316, F321, F304L, F316L |

| 3 | Umsesane wesiqingatha | ASTM A182-Gr F6a, ASTM A182-F22, ASTM A182-F304, F316, F321, F304L, F316L |

| 4 | Icwecwe leDiskhi | ASTM A182-Gr F6a, ASTM A182-F22, ASTM A182-F304, F316, F321, F304L, F316L |

| 5 | Isiqu | ASTM A182-Gr F6a, ASTM A182-F22, ASTM A182-F304, F316, F321, F304L, F316L |

| 6 | Gasket | I-Flexible+Graphite, iStainless Steel |

| 7 | Ibhonethi | ASTM A216-WCB, ASTM A217-WC1, WC6, WC9 C5, ASTM A351-CF8, CF8M, CF3, CF3M |

| 8 | Ngezantsi | I-ASTM A182-F304, F316 F321, F304L, F316L |

| 9 | Ukupakisha | Flexible+Graphite |

| 10 | Ukupakisha iGland | ASTM A216-WCB, ASTM A217-WC1, WC6, WC9 C5, ASTM A351-CF8, CF8M, CF3, CF3M |

| 11 | I-Stem Nut | Ingxubevange yobhedu |

| 12 | Ivili lesandla | I-ASTM A536 Gr 60-40-18, i-A216-WCB |

| 13 | Indawo yePleti | 25, 45, 304, 316, 304L, 316L |

| 14 | Stud | I-ASTM A193-B7, i-A320-B8, i-A193-B8M |

| 15 | Hex Nut | I-ASTM A194-2H, A194-8, A194-8M |

| Igama lenxalenye | Izinto eziphathekayo |

| Umzimba | 1.0619(A216 WCB), 1.7357(A217 WC6), 1.4408 (A351 CF8M) |

| Isihlalo | 13Cr, STL6 |

| Idiskhi | 2Cr13+QT, A105, F316 |

| Imvubu | SS304, SS316 |

| Isiqu | 2Cr13, F316 |

| Gasket | IGraphite+Intsimbi engatyiwayo |

| Ibhonethi | 1.0619(A216 WCB), 1.7357(A217 WC6), 1.4408 (A351 CF8M) |

| Bloti | A193 B7, A193 B16, A193 B8M |

| Nut | A194 2H, A194 4, A194 8M |

| Ukupakisha | Igraphite |

| Indlala | 1.0619(A216 WCB), 1.7357(A217 WC6), 1.4408 (A351 CF8M) |

| Akukho kubola.Isixhobo | A105, F304 |

| I-Stem Nut | GGG40.3, Cu Alloy |

| Gcoba ingono | Cu Alloy |

| Ivili lesandla | Intsimbi |

| Tshixa Nut | CS |

1.Isixhobo setywina esiBellow.Inxalenye ephambili yeevalvu zeglowubhu ezivaliweyo yintsimbi.Lunxibelelwano phakathi kwesigqubuthelo kunye nesiqu nge-automatic roll welding.Intsimbi evuzayo inokugcina isiqu esingavuziyo.

2. Uxhamle kwikhowuni kunye noyilo lobume obulungelelanisiweyo, idiski inomsebenzi othembekileyo wokutywinwa kunye nobomi benkonzo obude.

3.Uyilo olutywiniweyo oluphindwe kabini (i-bellows + ukupakisha) .I-Bellow kunye nokupakisha kunokukhusela ekuvuzeni kunye nokubonelela ngokusebenza kokutywina okugqwesileyo.

4.Gcoba ingono.Inokuthi ngokuthe ngqo Lubricate isiqu, i-nut kunye nomkhono.

5.Ergonomic ivili lesandla.Inika ubomi benkonzo obude kunye nokusebenza lula.

I-1.OEM kunye nokukwazi ukwenza ngokwezifiso

2.Our own foundry (Precision casting/Sand castings) ukuqinisekisa ukuhanjiswa ngokukhawuleza kunye nomgangatho

I-3.MTC kunye nengxelo yoHlolo iya kubonelelwa ngempahla nganye

4.Amava okusebenza atyebileyo kwii-odolo zeprojekthi

5.Izatifikethi ezifumanekayo:WRAS/ISO/CE/NSF/KS/TS/BV/SGS/TUV …